Banana Paper Manufacturing: A Sustainable and Eco-Friendly Alternative

Banana paper is manufactured using banana fibers as the primary raw material. This process promotes sustainability and helps reduce deforestation. Banana paper is popular due to its biodegradability, strength, texture, and contribution to local economies.

What Is Tree-free Paper?

Banana paper is made from the fibers of the banana plant. The banana tree’s trunk is used for production which is discarded after fruit harvesting. The plant’s fibers are extracted, processed, and then turned into paper sheets using traditional papermaking techniques. The process not only makes use of a plant that is otherwise wasted, but it also offers a biodegradable and sustainable alternative to conventional paper.

Handmade tree-free Paper making is an environment-friendly and nonhazardous method. The paper made with tree wood uses more chemicals.

The Banana Paper Manufacturing Process

The process of banana paper manufacturing involves several key steps, starting from the collection of banana fibers to the production of finished paper products. Below is a detailed breakdown of the key stages:

How do you make banana paper?

- Separate the Layer of Banana bark.

- Then cut the bark layers into 1-2 inches pieces.

- And cook them for around 2 hours.

- Use a stainless-steel pot for cooking—cooked fiber with water.

- Wash them and use a mixer or mechanized beater for pulping.

- Mix the pulp with some water in a tray or horizontal tank.

- With the help of mold and deckle form a sheet of paper.

- The GSM of paper depends on the pulp and water ratio.

- Sun dry the sheet.

- Your first handmade tree-free paper is ready.

1.Separate the Layer of Banana bark.

The first step in the banana paper manufacturing process involves collecting the banana pseudo stems, which are typically discarded after the bananas are harvested. These pseudo stems contain long, strong fibers that can be extracted and used to make paper.

2. Extracting the Fibers

This process involves stripping the outer layers of the pseudo stem to expose the strong, fibrous interior. The fibers are then separated and cleaned to remove impurities.

3. Cut the banana fiber into 1-2 inches pieces.

Once the banana fibers are extracted and cleaned, they are cut into 1-2 inches pieces. They are washed and cleaned to remove dust and other particles.

4. Cook them for around 2 hours

The next process is to soak the fibers in water. After that, they are cooked for 2 hours to break cellulose and separate the lignin.

5. Wash them and make a pulp.

First of all, the cooked fiber is washed to separate the black liquor. Then the cooked fiber is converted into pulp by grinding the fibers into smaller pieces. The Hollander beater is used in high-capacity plants. You can use a mixer grinder as an alternative in small volumes.

6. Forming the Paper Sheets

Mix the pulp with some water in a tray to form a pulp sheet. The ratio of pulp and water decides the GSM of paper. Mold or screen is used to insert in a given mixture which forms a layer of pulp and excess water is drained out.

7. Dry the pulp sheet

The sheets are then dried, either through air drying or by using mechanical drying equipment. Sun drying is also an option but it changes the shape of the pulp sheet.

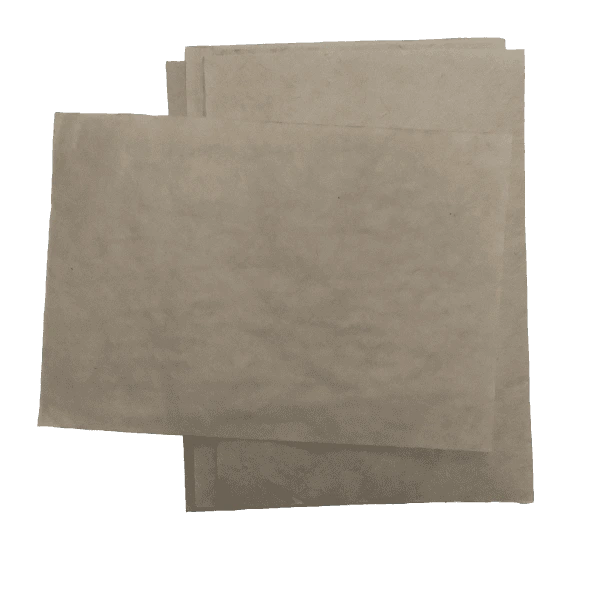

Once the paper is dry, it is cut into the desired size and shape for various applications.

8. Finishing Touches

The calendaring process improves the surface smoothness and strength of banana paper.

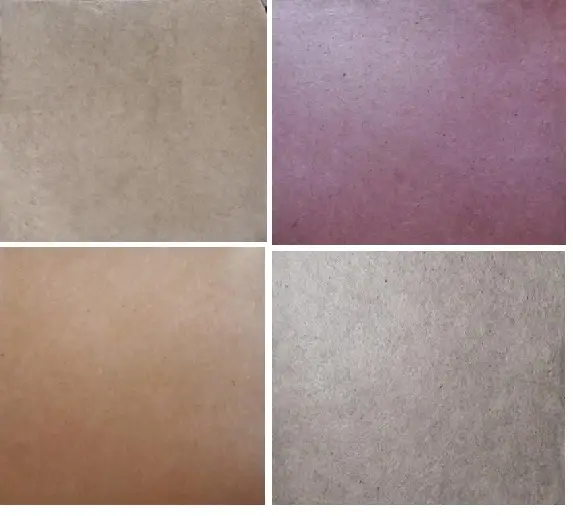

Also, you can add color or texture, or coat the paper with natural oils or resins to improve its durability and water resistance.

The finished product is then ready for use.

Banana Fiber as an alternative paper

Tons of banana stems generate waste every year. The banana stem fiber is the best alternative to replace plastic and paper. The banana plantation growth will increase the yearly banana stem waste. So, convert this waste into wealth by extracting the fibers.

Workers manually and mechanically extract banana stem fiber. The manual process produces a very low quantity, and the banana fiber extraction machine quickly performs the mechanical process.

India is the world’s largest banana producer with an annual production of 24.8 million tonnes. It accounts for 13% of the total area under production and 33% of the production of fruits. Within India, Maharashtra has the highest productivity of 65.70 metric tonnes /ha. against a national average of 30.5 tonnes/ha.

Why is banana paper better than normal paper?

It has a shelf life of over 100 years. Which makes it the strongest long fiber ever found among natural fibers.

It can be folded for as many as 3,000 times. It can use currency and value-able documents.

Less water is required for manufacturing.

It is stronger than normal paper.

Banana Fiber Paper uses

- Manufacturers use it for making disposable dishes, paper cups, disposable glasses, and carry bags.

- Also used for Men’s as well as ladies’ wallets.

- It is used for making handicrafts and home decor.

- It is used for currency notes in Germany and a trial run in India.

- Designers used this for printing business cards and greeting cards, beautiful visiting cards, and wedding cards.

- This paper is used for making gift boxes, notebook covers, and drawing paper.

- It is best for sanitary towels and diapers.

- Benign paper uses this paper for booklamps to replace the wood.

- Use for filter paper, pen stands, photo frames, and lampshades, etc.

- Use this paper for writing and painting.

- Used to store food and to serve foodstuffs.

- Artists use it for various handicrafts and arts.

Banana papercraft

some examples are the Banana Paper Book lampshade,

Booklight for reading,

Small book lamp,

Book and Lamp,

Folding Night Lampshade,

LED Booklamp,

Mini Table Lampshade,

Ceiling Lampshade for Bedroom,

Tree-free Paper Mens Wallet.

The Future of Banana Paper Manufacturing

As sustainability becomes an increasingly important focus for businesses and consumers alike, the demand for eco-friendly products is expected to rise. Tree-free paper manufacturing offers a viable solution to the global problem of deforestation and paper waste, making it an important part of the future of the paper industry.

Investments in Tree-free paper technology, such as improved extraction methods and automated processing, could further streamline production and lower costs, making this paper an even more attractive option for large-scale manufacturers.

Conclusion

Banana paper manufacturing represents a significant step toward a more sustainable future, offering an innovative way to reduce waste, conserve forests, and promote eco-friendly practices. By harnessing the natural strength and biodegradability of banana fibers, this method of paper production provides an environmentally responsible alternative to traditional paper. As demand for sustainable products continues to grow, banana paper will play an essential role in shaping the future of the paper industry.

If you’re looking for a green solution to your paper needs, consider exploring the benefits of banana paper – an eco-friendly, biodegradable, and durable material that offers both environmental and economic advantages.